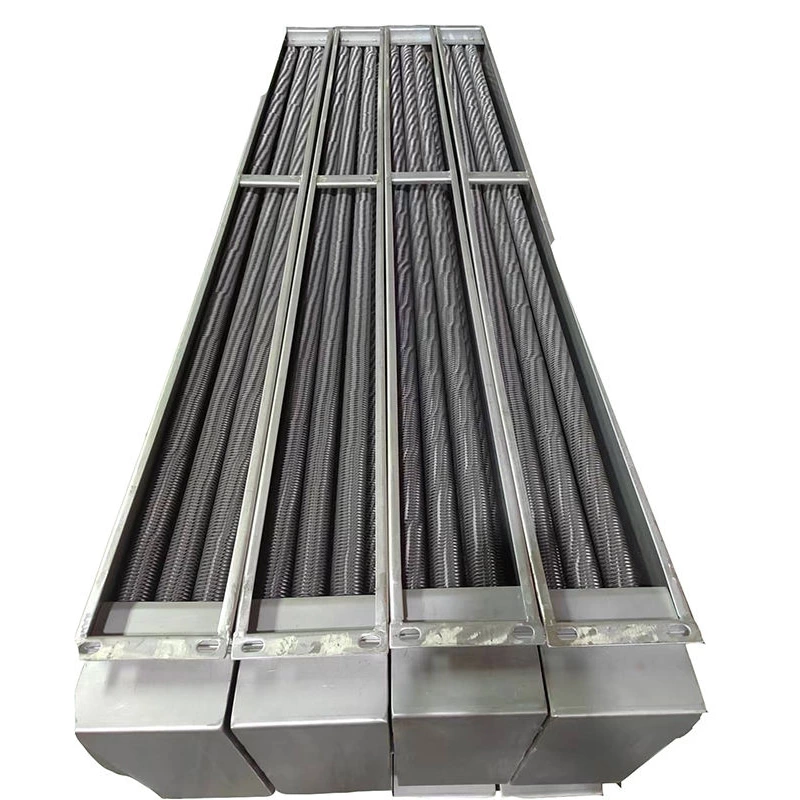

Fin Heat Exchanger

Fin-tube heat exchangers are a type of partitioned heat exchanger whose core feature is the installation of extended surfaces called "fins" on the outer or inner surface of a common base tube. These fins greatly increase the heat transfer area of the heat exchanger, thereby significantly enhancing the heat transfer process.

- Extremely High Heat Transfer Efficiency:: Fins not only increase the surface area but, more importantly, disrupt the fluid boundary layer. The presence of the fins continuously divides and turbulents the airflow, thinning the thermal boundary layer and significantly improving the heat transfer coefficient on the gas side, thus achieving overall high heat transfer efficiency.

- High Space Efficiency::Due to their high heat transfer efficiency, fin-tube heat exchangers require far less tubing and space than bare tube heat exchangers to achieve the same amount of heat transfer. This results in a compact and relatively lightweight device, making it ideal for space-constrained applications.

- Highly Cost-Effective: Easy to Manufacture and Maintain: The design and manufacturing process are highly standardized and mature, with numerous manufacturers worldwide, ensuring relatively manageable production costs.

- Various Forms: Fin-tube heat exchangers can be designed in a variety of configurations to suit different working fluids and operating conditions. Options include flat fins, corrugated fins, windowed fins, and serrated fins. Different fin shapes have varying effects on flow disturbance and heat transfer enhancement, allowing for optimization to meet specific needs.

- Strong Pressure Capacity: The heat transfer medium flows within the tubes, allowing them to be designed to withstand higher pressures. The air or flue gas on the fin side, on the other hand, is typically at a lower pressure. This structure separates the high-pressure side from the expanded surface, ensuring both safety and efficient heat transfer.