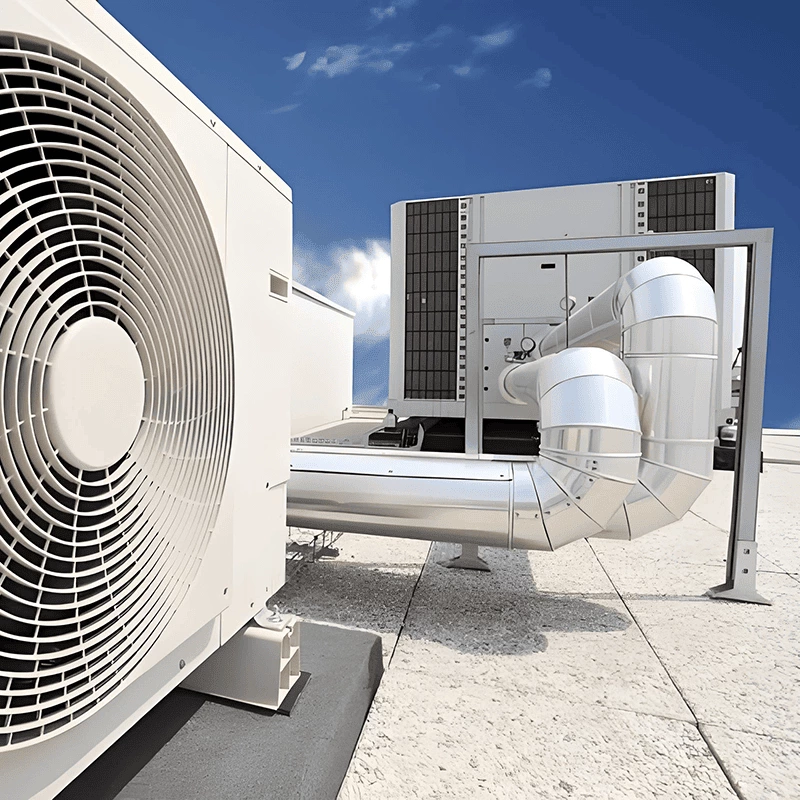

Fin heat exchangers are highly efficient and versatile solutions designed for air and gas heat transfer applications, offering excellent thermal performance within a compact and lightweight structure. By integrating extended fin surfaces onto the tubes, they significantly increase the effective heat transfer area and enhance airflow turbulence for greater efficiency. Each unit is engineered for optimal duty performance and durability, ensuring stable operation under varying temperature and pressure conditions. This makes fin heat exchangers an ideal choice for HVAC, refrigeration, power generation, and industrial cooling systems where space, efficiency, and reliability are essential.

Fin Heat Exchanger