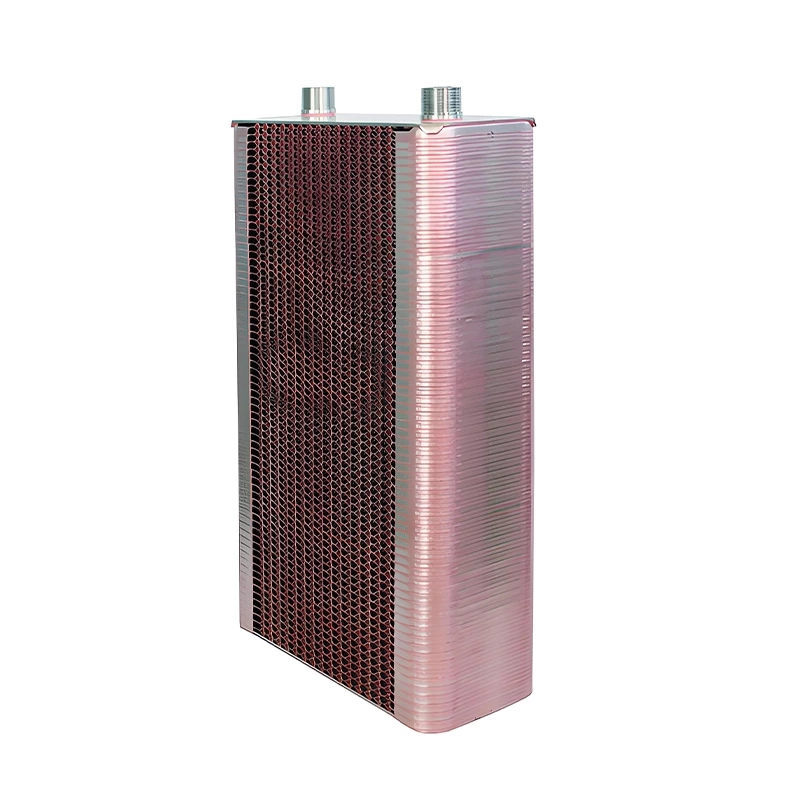

Brazed Plate Heat Exchanger

A brazed plate heat exchanger (BPHE) is a compact, efficient heat exchanger made from a series of corrugated metal plates joined together using a high-temperature brazing process in a vacuum brazing furnace. It can be considered an upgraded version of the removable plate heat exchanger, but because the plates are permanently brazed together, they cannot be disassembled.

- High Heat Transfer Efficiency:: The special corrugated design on the plates creates intense turbulence even at extremely low flow rates, significantly disrupting the thermal boundary layer and resulting in a heat transfer coefficient significantly higher than that of traditional shell-and-tube heat exchangers.

- Compact Size:: Due to their high heat transfer efficiency, fewer plates are required, and brazing eliminates the need for a heavy compression frame. Brazed plate heat exchangers typically have a volume of only 10% to 50% of that of shell-and-tube heat exchangers for equivalent heat transfer capacity, significantly saving space.

- High Pressure Resistance: Compared to removable plate heat exchangers, the brazed structure eliminates the need for gaskets and bolted frames, significantly enhancing overall rigidity. The welded joint evenly distributes pressure, preventing seal failure or structural deformation, ensuring stable operation under high-pressure conditions. Suitable for refrigerant, high-pressure oil, or steam systems, they are suitable for high-temperature applications.

- High Temperature Resistance: Without the constraints of rubber gaskets and metal frames, brazed plate heat exchangers maintain excellent sealing performance at higher temperatures. The integrated structure of solder and stainless steel plates can withstand long-term heat loads exceeding 200°C, making it suitable for applications such as high-temperature heating, condensation, and thermal oil transfer.

- Low retention volume: The flow path volume between the plates is very small, meaning that the total amount of media retained in the system is minimal. This is particularly important for expensive, toxic, or environmentally hazardous fluids, saving costs and improving safety.