Mvr Single-effect Plate Evaporation Concentration System For Lactic Acid

Process core: Single-effect mechanical vapor recompression (MVR) technology is adopted. This is an efficient and energy-saving evaporation method. The

Sodium Chloride Wastewater Double-effect Plate-type Rising Film+tube Forced Circulation Evaporation Crystallization

Processing medium and purpose: Medium: industrial wastewater mainly containing sodium chloride. From chemical, pharmaceutical, food processing or coal

Lithium Sulfate Triple-effect Tube +MVR Forced Circulation Evaporation Crystallization System

Handling media and materials: Medium: lithium sulfate solution. This is a chemical material with high added value but may be corrosive. &n

Five Effect Apple Juice Concerntration Evaporator

1.Processing materials and targets: Material: apple juice. Initial state: the original juice (usually about 10-12°Brix). The final product: concentrat

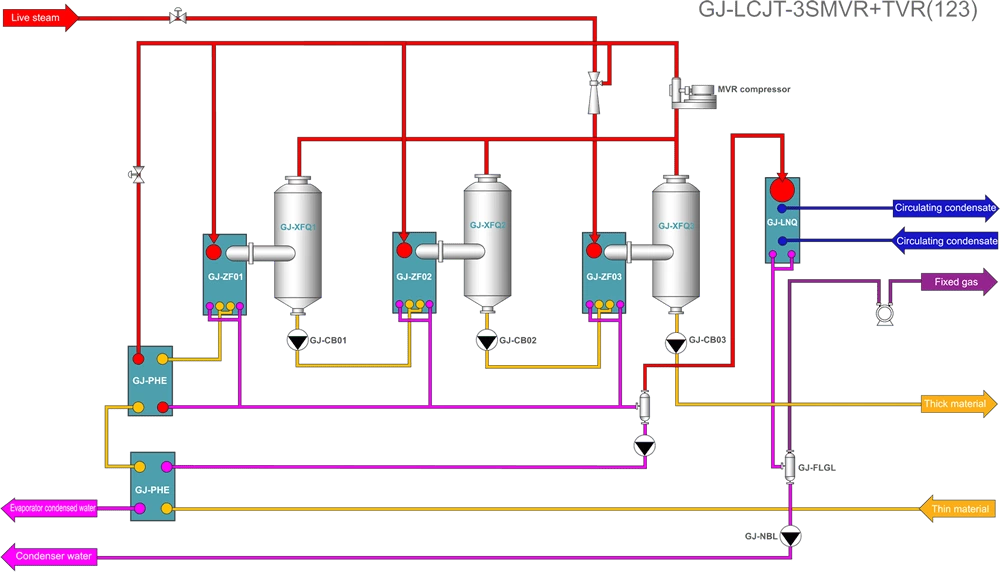

MVR+TVR Plate Evaporation Concentration System for Maltooligosaccharides

Process core: the combined system of MVR single-effect and multi-effect evaporator is adopted. This design is very energy-saving, with MVR as the main

Calcium Lactate Double Effect +TVR Evaporation System

Process core: The combined system of double-effect evaporation and thermal steam recompression (TVR) is adopted. In this system, two evaporator