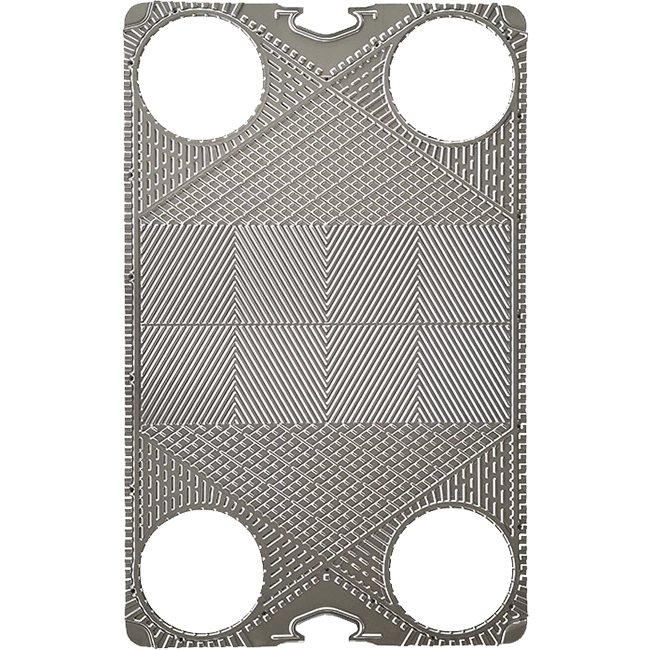

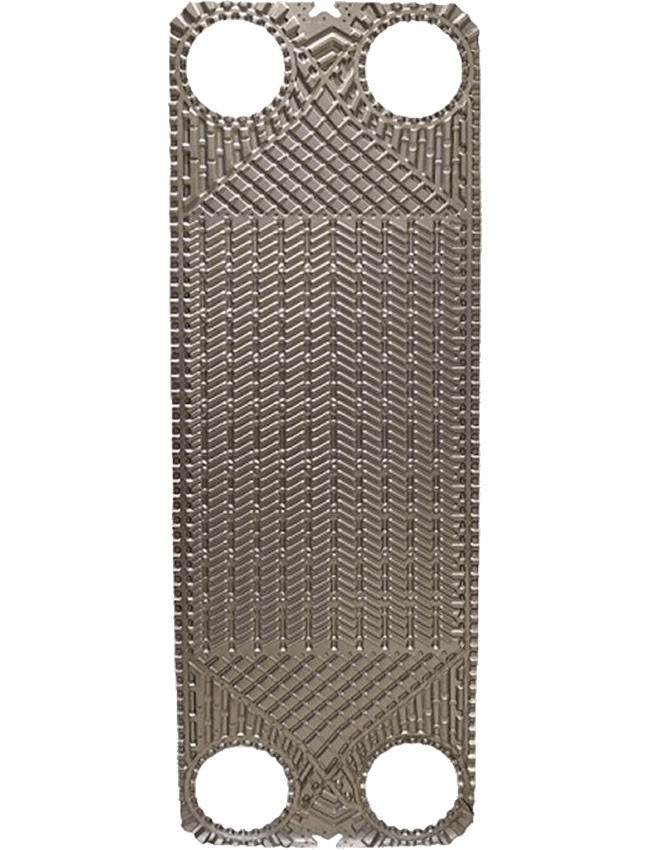

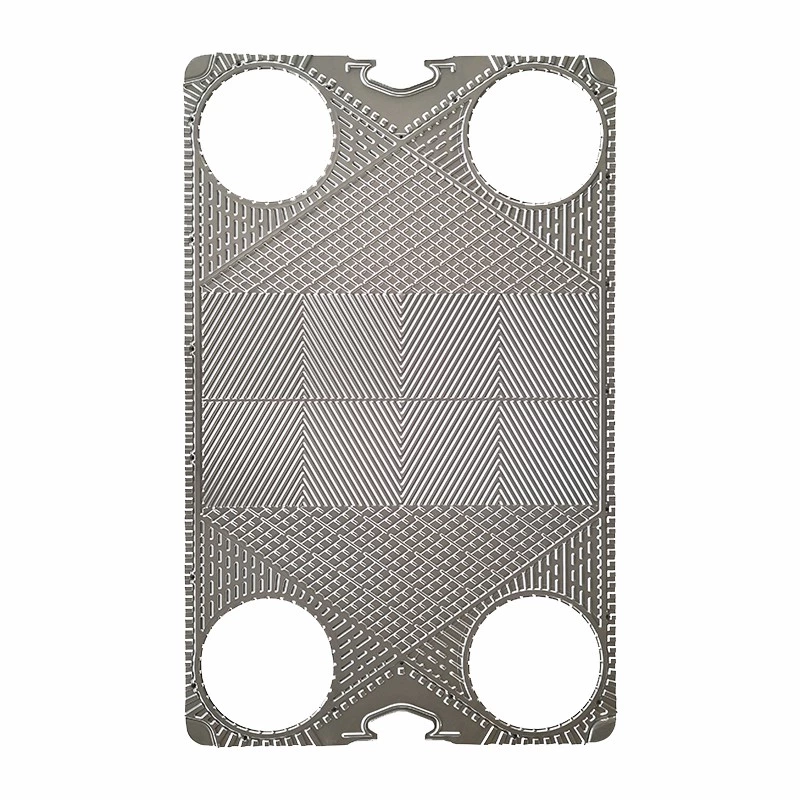

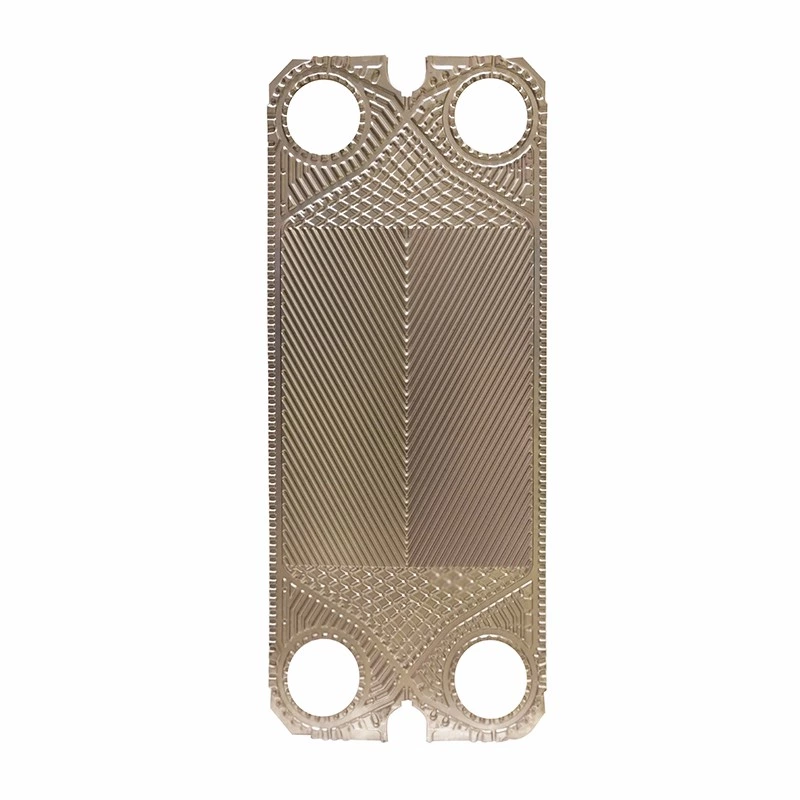

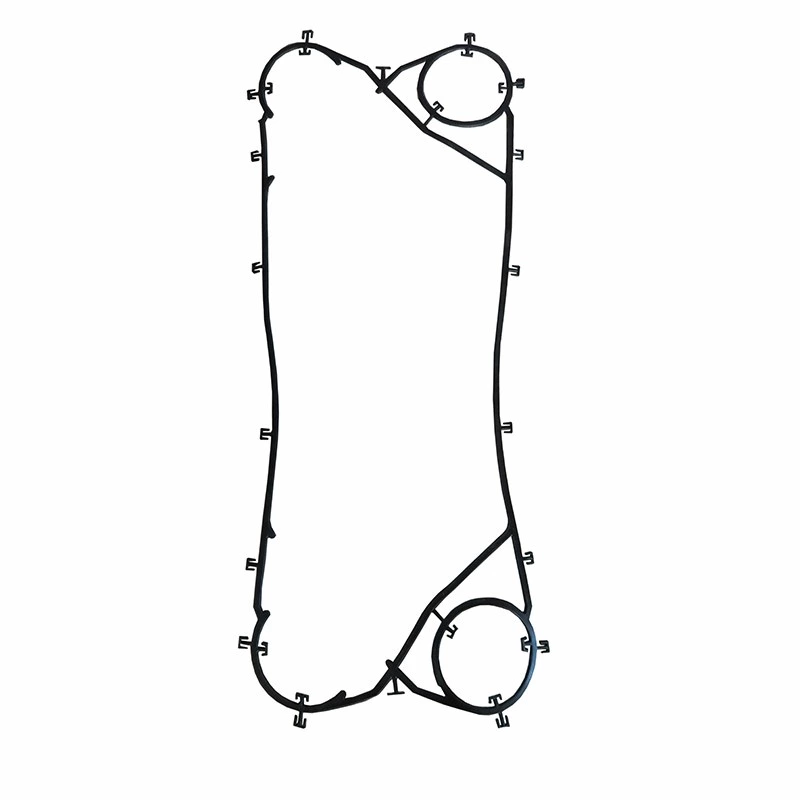

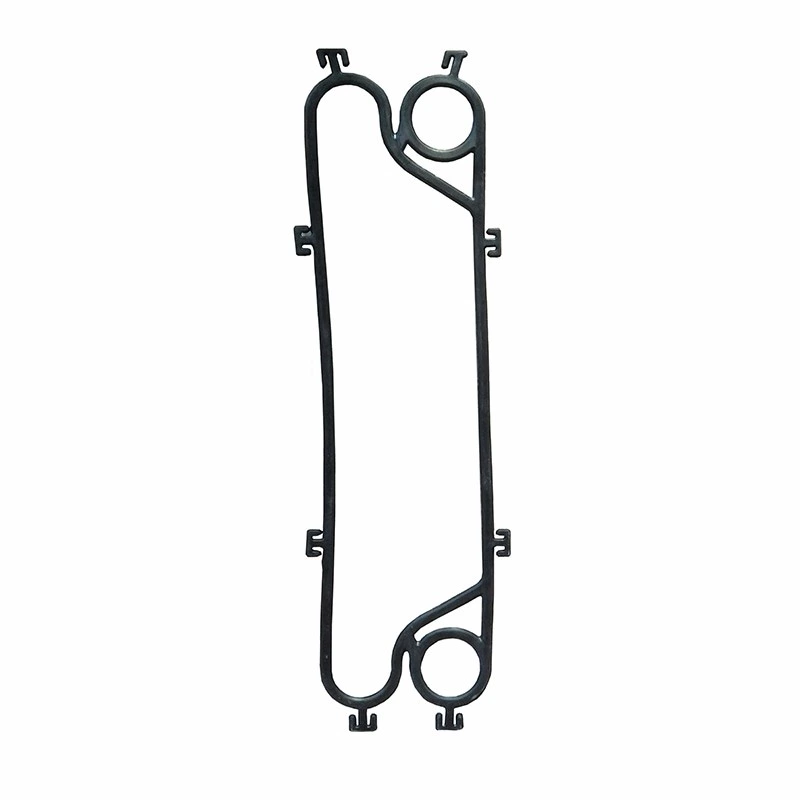

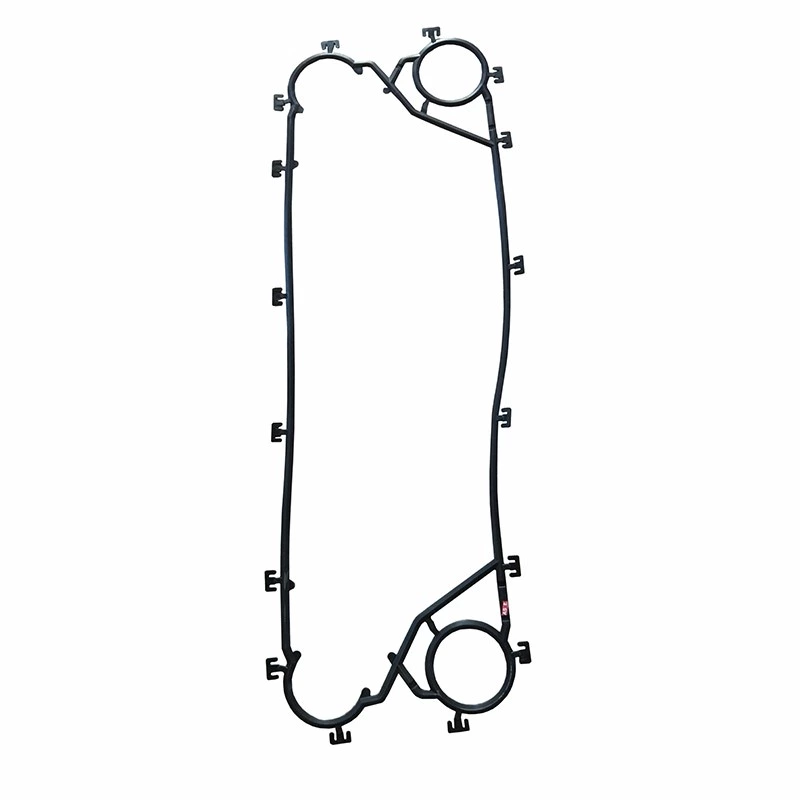

S-JE offers a complete range of accessories designed to complement and enhance the performance of our heat exchange and process systems. Each component—from gaskets and seals to connectors and fittings—is precision-engineered for durability, easy installation, and reliable long-term operation.

Accessories