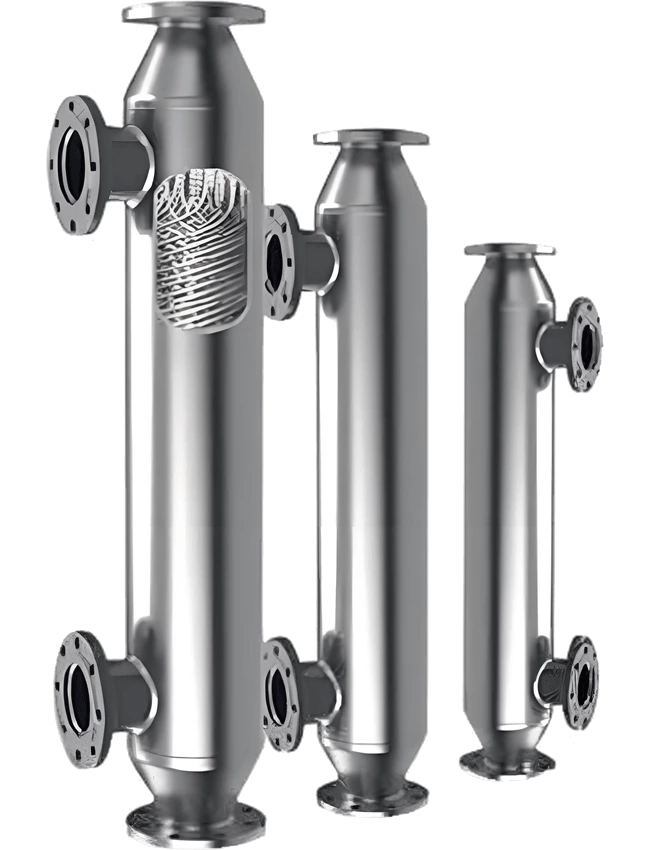

Our tubular heat exchangers are built with high mechanical strength to accommodate large temperature and pressure differences. The smooth internal surfaces promote efficient heat transfer and easy cleaning, reducing downtime and maintenance costs. They are ideal for chemical, food, and power generation industries where reliability and cleanliness are essential.

Shell And Tube Heat Exchanger