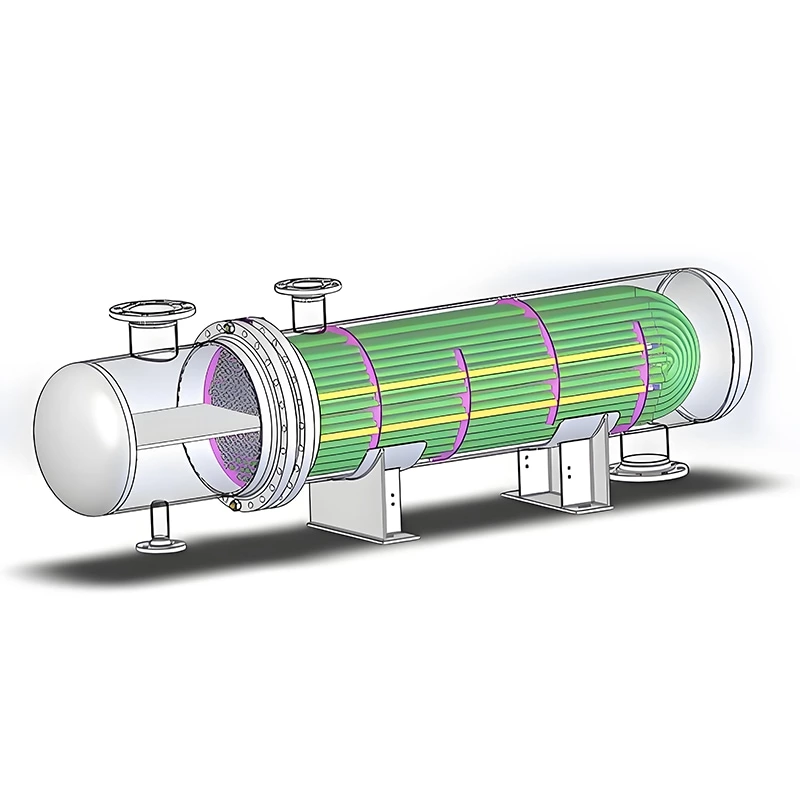

U-tube Heat Exchanger

A U-tube heat exchanger is a type of shell-and-tube heat exchanger. Its core feature is that each heat exchange tube is bent into a U-shape, with both ends fixed to the same tube sheet, forming a free-standing "U" bundle. It is a very common heat exchange device in industries such as chemical, petroleum, pharmaceutical, and energy.

- Strong thermal compensation capability: This is the most prominent advantage of the U-tube heat exchanger. It eliminates the need for expensive expansion joints, as is the case with fixed tubesheet heat exchangers, making it ideal for high-temperature and wide temperature differential applications.

- Simple structure and low cost: With only one tubesheet, the manufacturing process is relatively simple compared to fixed tubesheet or floating head heat exchangers with double tubesheets, resulting in fewer sealing points and lower manufacturing costs.

- No cross leakage: In a U-tube heat exchanger, the tubesheet is integral to the shell and connected to the shell flange. Even if a leak occurs in the tubesheet seal, the fluid escapes to the atmosphere, preventing cross-mixing between the tube side and the shell side.

- Easy to clean: Debris on the shell side can be cleaned directly with a high-pressure water jet or mechanical tools. While mechanical cleaning of the tube interior is difficult due to the U-bend, chemical cleaning is possible.