Plate Heat Exchanger FN15

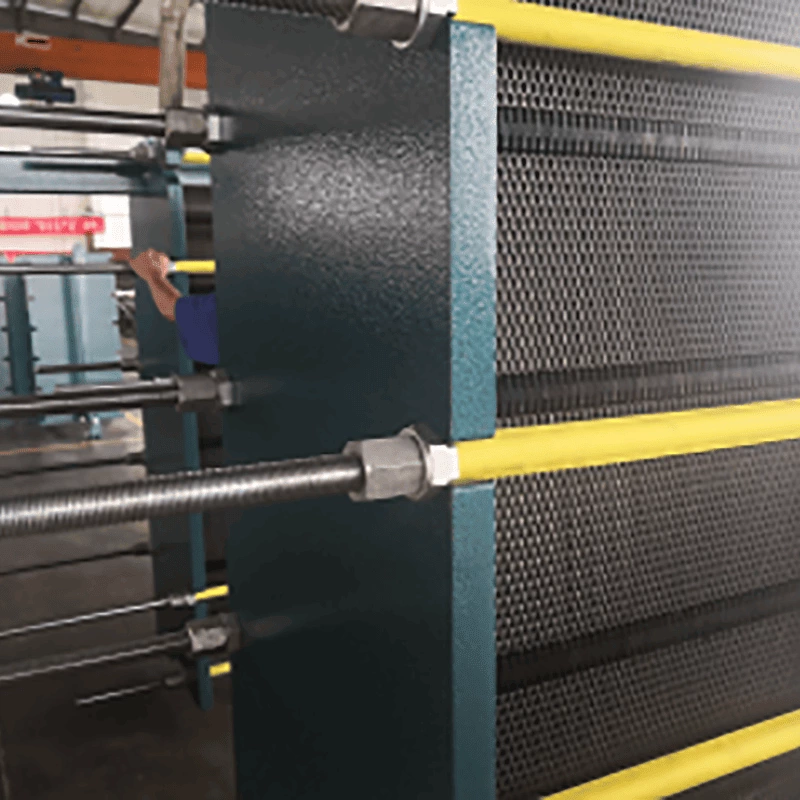

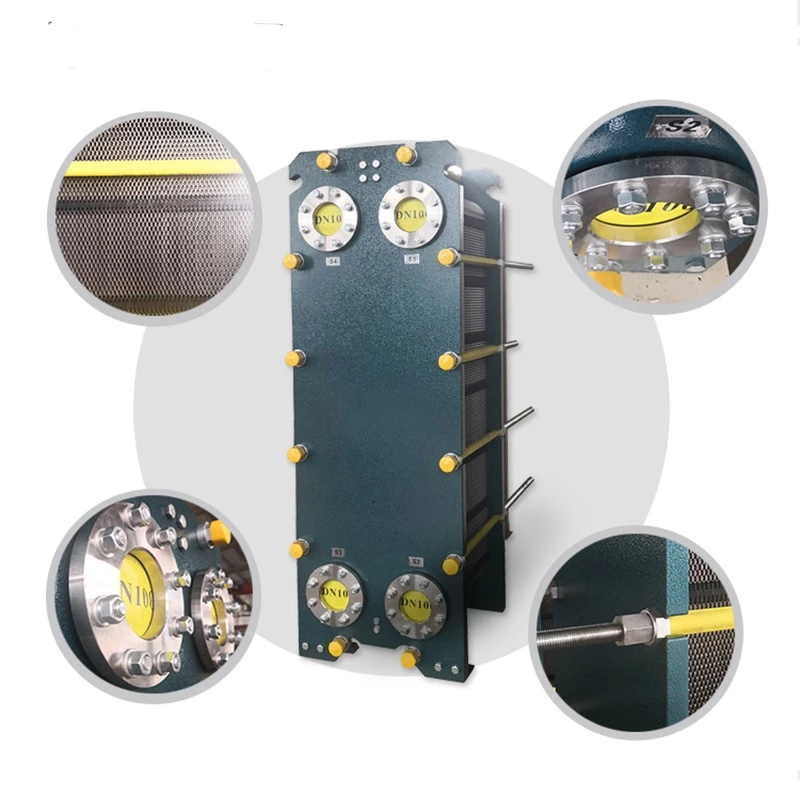

A plate heat exchanger is a highly efficient heat exchanger composed of a series of stacked, corrugated metal plates. Thin rectangular channels are formed between the plates, through which heat is exchanged. Compared to shell-and-tube heat exchangers, they offer significantly higher heat transfer coefficients while occupying a smaller footprint, given the same flow resistance and pump power consumption.

- High Heat Transfer Efficiency: The corrugated design of the plates creates intense turbulence even at low flow rates, significantly disrupting the thermal boundary layer and reducing thermal resistance. Its heat transfer coefficient is typically 3-5 times that of a shell-and-tube heat exchanger.

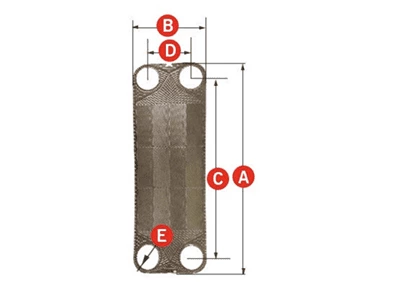

- Compact Structure and Small Footprint: The thin, tightly packed plates provide a large heat transfer area per unit volume.To achieve the same heat transfer performance, the footprint and volume of a plate heat exchanger are significantly smaller than those of a shell-and-tube heat exchanger.

- Low Heat Loss: Only the plate edges and the pressure plate are exposed, eliminating the need for additional insulation, resulting in negligible heat loss.

- High Flexibility and Easy Adjustment: When process requirements change, the heat transfer area can be easily adjusted to accommodate new operating conditions by simply adding or removing plates.

- Large Logarithmic Mean Temperature Difference and Small End-Temperature Difference: Plate heat exchangers enable pure countercurrent heat transfer, resulting in a larger logarithmic mean temperature difference between the two fluids and a stronger heat transfer driver.

- Low fouling coefficient: Strong turbulence prevents suspended matter from settling on the plates. The corrugations of the plates also provide a self-cleaning effect, reducing scaling.

- Suitable for a variety of media: By replacing the intermediate plate or adopting a dual-plate design, a single unit can simultaneously handle heat exchange for two or more media.

- Easy to install and maintain: Maintenance and cleaning are extremely convenient. Simply loosen the compression bolts to open the unit and thoroughly inspect and mechanically clean the plates.