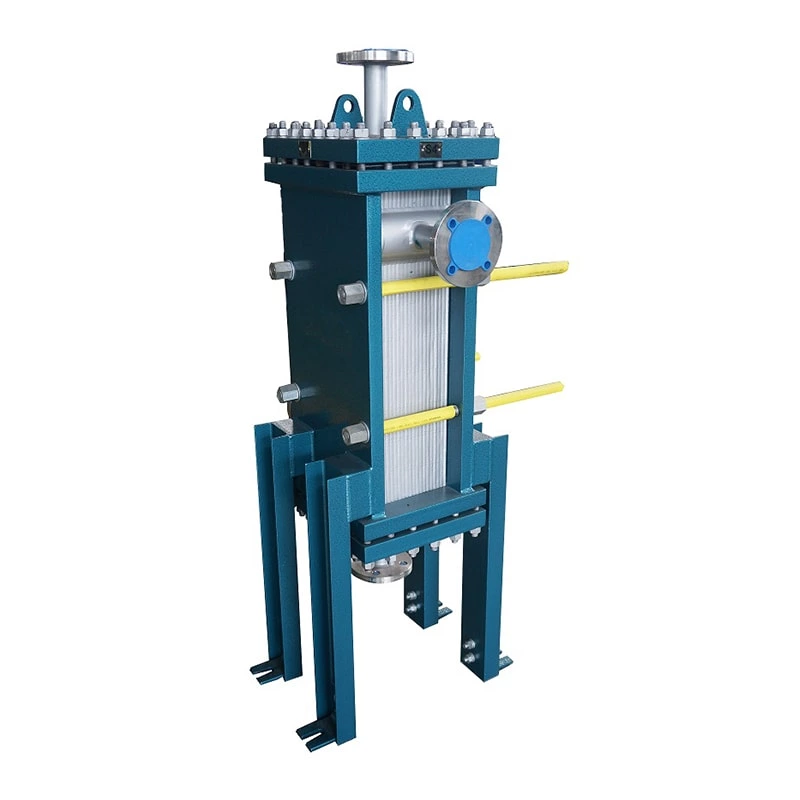

Fully Welded Plate Heat Exchanger

The fully welded plate heat exchanger is a heat exchange device that permanently connects the plates of the traditional plate heat exchanger into an integral core through welding. The welded structure overcomes the temperature and pressure resistance limitations and media compatibility issues caused by the rubber gaskets of the detachable plate heat exchanger.

- High-pressure resistance:: The plate pack is permanently welded using laser or plasma welding, eliminating the need for rubber gaskets. This structure provides exceptional sealing strength and ensures reliable operation under high-pressure conditions where conventional detachable plate exchangers may fail.

- High-temperature resistance:: With no rubber gaskets involved, the fully welded construction allows the heat exchanger to withstand significantly higher temperatures. It performs safely and efficiently in high-temperature processes that exceed the limits of gasketed plate heat exchangers.

- High corrosion resistance: Not only can it be used with higher-grade stainless steel, but also with specialty materials such as Hastelloy, titanium, and nickel. Furthermore, since it lacks rubber gaskets, it is not limited by the gasket material's temperature and corrosion resistance.

- High heat recovery rate: It can heat the cold fluid to a temperature closer to the hot fluid outlet, making it ideal for low-temperature waste heat recovery and maximizing energy recovery.

- Small footprint: Compact structure and relatively low material consumption make it easier to install and transport, resulting in lower overall costs