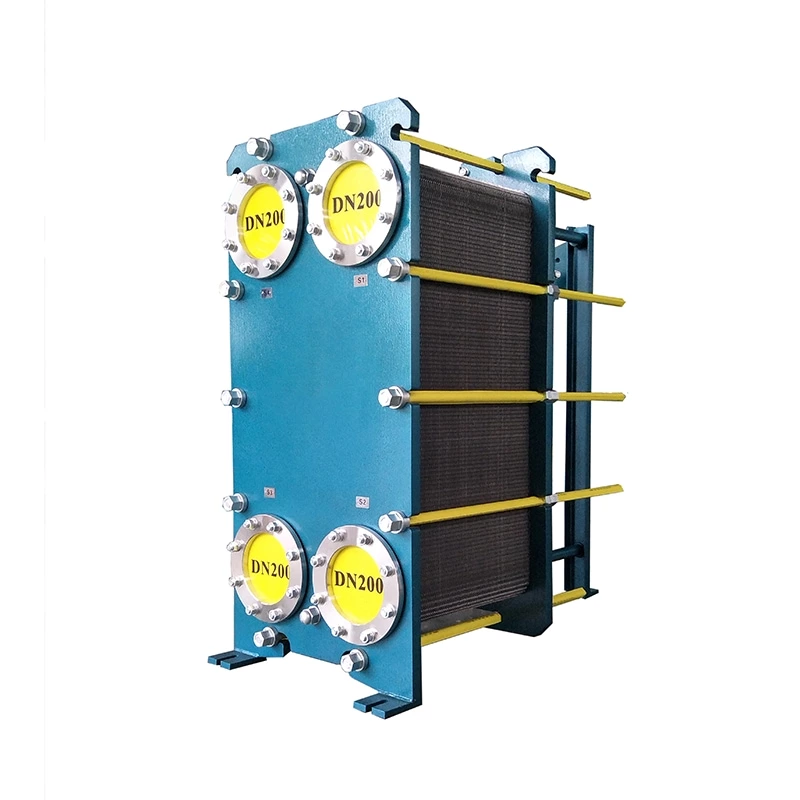

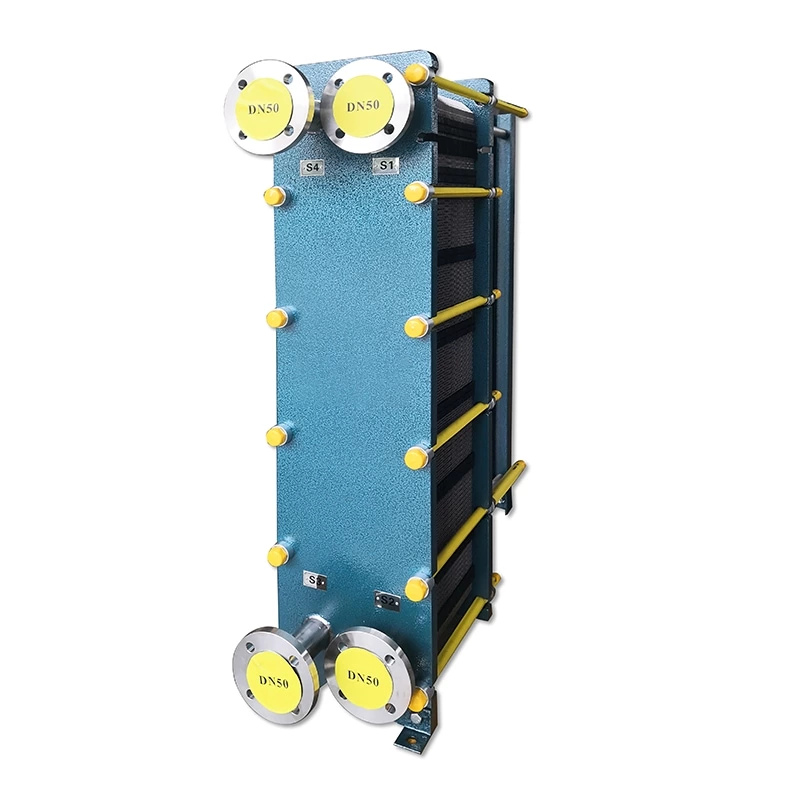

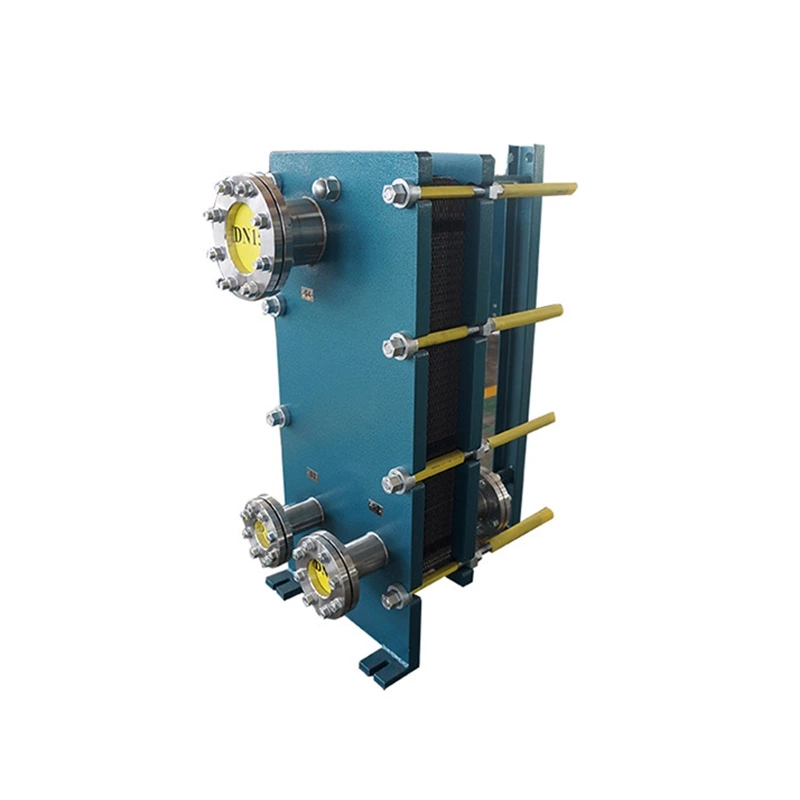

Semi-welded Plate Heat Exchanger

Semi-welded plate heat exchangers combine the features of removable plate heat exchangers and fully welded plate heat exchangers. They consist of a series of corrugated metal plates that form flow paths for two fluids (usually the medium side and the cooling/heating side).

- High Safety:: Semi-welded plate heat exchangers confine hazardous media within welded channels, completely eliminating the risk of leakage from the plates into the environment, offering exceptional safety.

- Compact Structure:: They retain the inherent turbulent flow design, high heat transfer coefficient, and compact structure of plate heat exchangers. For the same heat transfer capacity, their volume is significantly smaller than that of shell-and-tube heat exchangers.

- High Pressure Resistance: Compared to removable plate heat exchangers, the welded modules of semi-welded plate heat exchangers offer enhanced sealing and structural stability. The welded channels can withstand higher operating pressures, eliminating the risk of leakage due to gasket aging or failure. They are suitable for applications such as high-pressure steam, refrigerants, and high-pressure process fluids.

- High Temperature Resistance: Because the welded structure eliminates the need for rubber gaskets, semi-welded plate heat exchangers maintain stable operation even in high-temperature environments. They can withstand temperatures far exceeding those of conventional removable plate heat exchangers, making them suitable for high-temperature heating, hot oil circulation, and other high-temperature heat transfer processes, ensuring long-term, safe, and reliable heat transfer performance.

- High Economic Benefitst: While the initial investment is higher when handling hazardous or high-pressure media, the enhanced safety and reliability of these solutions prevents production downtime, product loss, or safety incidents caused by leaks, resulting in superior cost-effectiveness over the entire lifecycle.