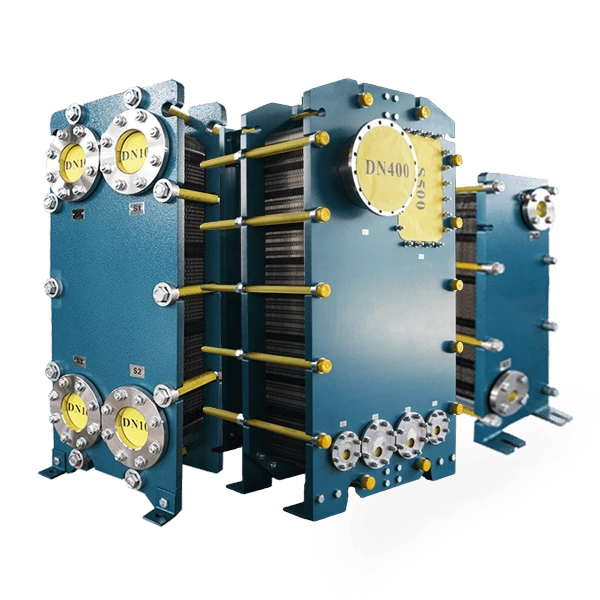

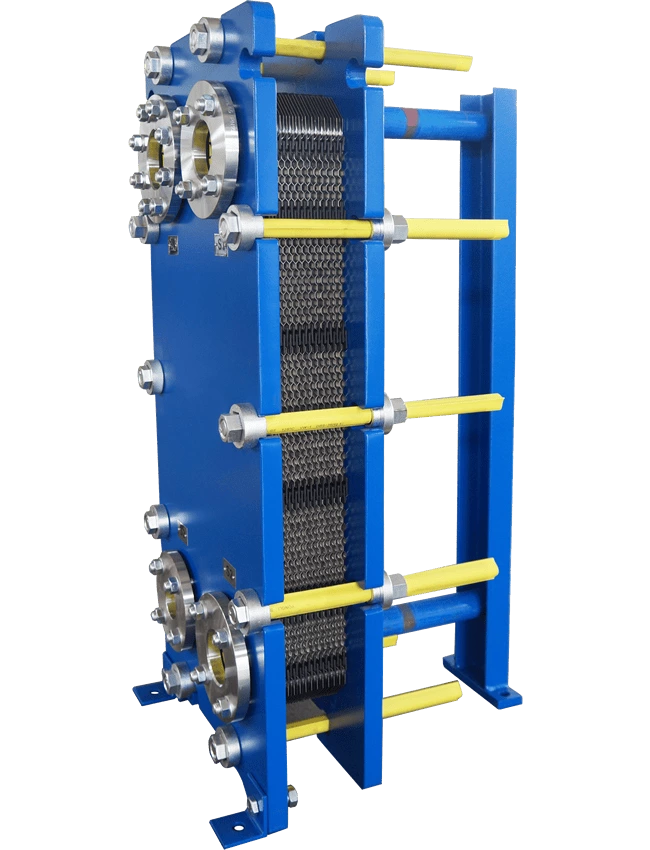

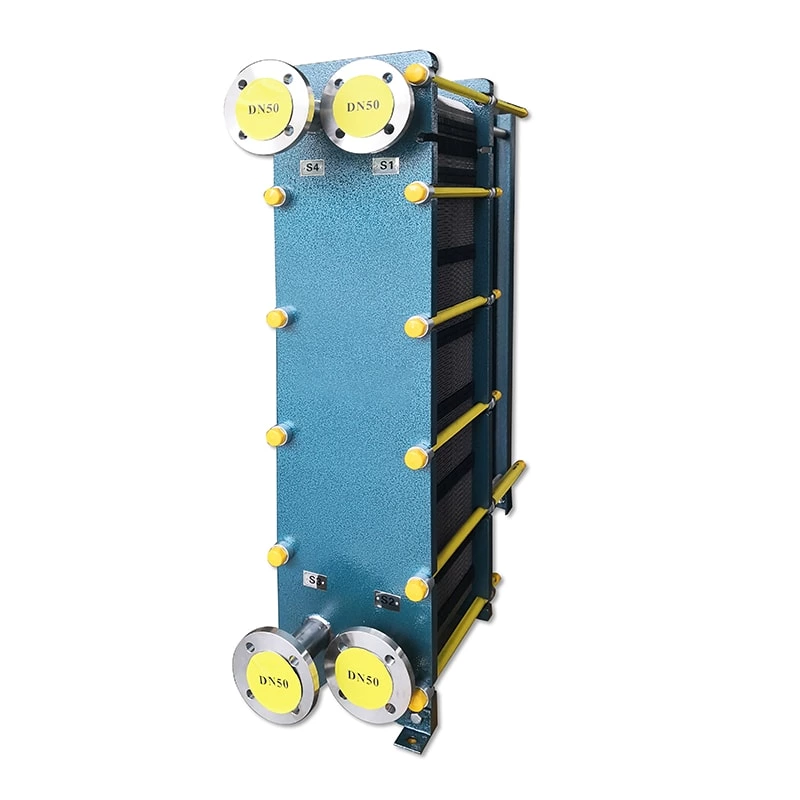

S-JE plate heat exchangers deliver efficient, reliable, and flexible performance for a wide range of heating and cooling applications. Each unit is engineered for optimal heat transfer efficiency and ease of maintenance, featuring a durable structure and high-quality materials that ensure long-term operation. Designed to handle demanding industrial conditions, S-JE plate heat exchangers provide stable performance, excellent corrosion resistance, and extended service life across diverse industries.

Plate Heat Exchanger